What is Combustible Dust? Does My Company Have It?

Combustible dust is a very serious hazard at industrial facilities, and one that must be addressed thoroughly and carefully with a combustible dust collection plan.

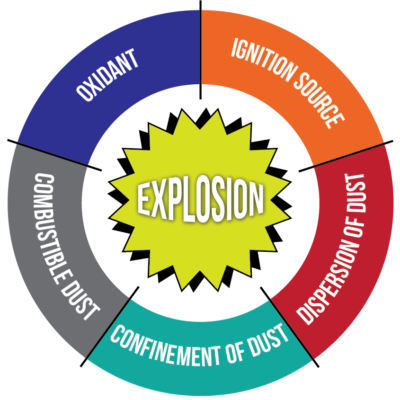

A variety of dusts can cause fires and even explosions if not handled properly. It’s essential to know what kind of dust you have and what conditions could lead to a combustible dust explosion.

Learn more about the five elements of the “dust explosion pentagon”

Testing to Determine if Your Dust is Combustible Dust

Working with a reputable testing company to conduct a combustible dust hazard analysis of your facility is an imperative. This test will determine what kind of dust is produced by your various industrial processes, and whether they are combustible.

Summit recommends working with Fauske. They are a very reputable third-party testing company. We know their testing protocol and can assist in simplifying the testing process.

How is Dust Combustibility Measured?

Dust combustibility is determined by measuring the explosive index (Kst) and the maximum pressure rise (Pmax) of your dust.

Any Kst Value Above Zero Must be Addressed

The Kst and Pmax values of your dust will indicate what dust collection, explosion ventilation, and fire suppression system your company will need.

When working with Summit, from testing through system design, installation and maintenance, we’ll help you navigate the process. Be assured. Your company’s combustible dust issue will be simplified by Summit — and the end result will be cost effective.

Summit has more than 120 years of combined experience in combustible dust collection projects, and we never overengineer solutions. We have the expertise needed to provide the specific solution you need to protect your workers and facilities, while keeping a steady eye on your Total Cost of Ownership.

Typical Kst values of some dusts commonly found in industrial facilities:

COMMON DUSTS |

KST VALUE |

|---|---|

| Activated Carbon | 44 |

| Aluminum Powder | 400 |

| Asphalt | 117 |

| Charcoal | 117 |

| Cotton | 24 |

| Milk Powder | 90 |

| Paper Tissue Dust | 52 |

| Rice Starch | 190 |

| Soap | 111 |

| Soy Bean Flour | 110 |

| Toner | 145 |

| Wood Dust | 102 |

NFPA Standards

If you’re weighing your options when it comes to combustible dust, there’s no better place to get your information than the National Fire Prevention Association (NFPA) and Occupational Safety and Health Administration (OSHA).

The NFPA has established seven standards that pertain to combustible and explosive dusts, and dust collection which your company is obligated to understand and comply.

Summit is here to help navigate the standards and ultimately engineer a combustible dust collection system to keep your business within compliance.

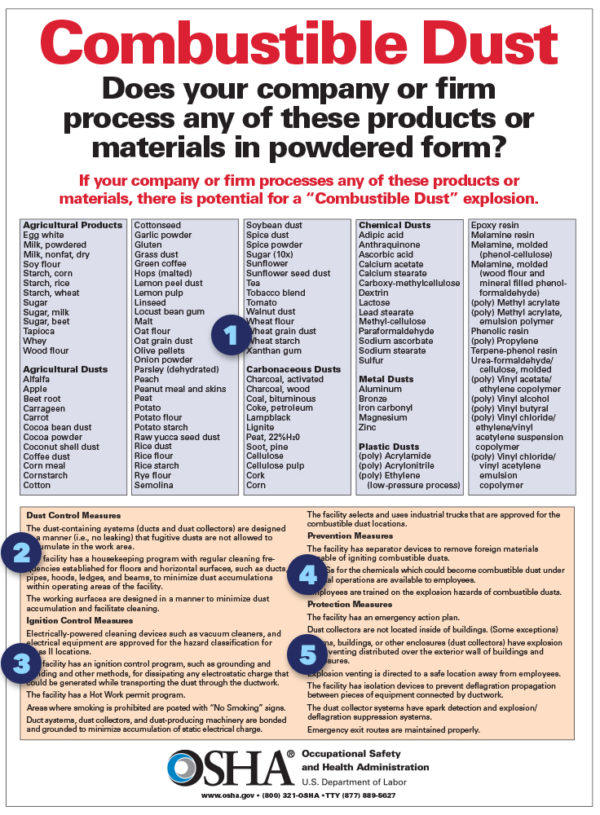

OSHA Recommended Measures

OSHA has developed a poster identifying the types of dust that are potentially combustible and explosive, and the necessary measures to prevent a fire or explosion from happening.

- A complete list of materials which can potentially produce combustible dust during the manufacturing process, including Agricultural Products, Agricultural Dusts, Carbonaceous Dusts, Chemical Dusts, Metal Dusts, and Plastic Dusts

- Dust control measures to explain the importance of dust collection systems

- Ignition control measures to outline how to avoid igniting combustible materials

- Prevention measures to address ways to keep explosions and fire from occurring

- Protection measures to ensure general safety precautions are in place